Certification

Criteria for VERT® Emission Control Systems

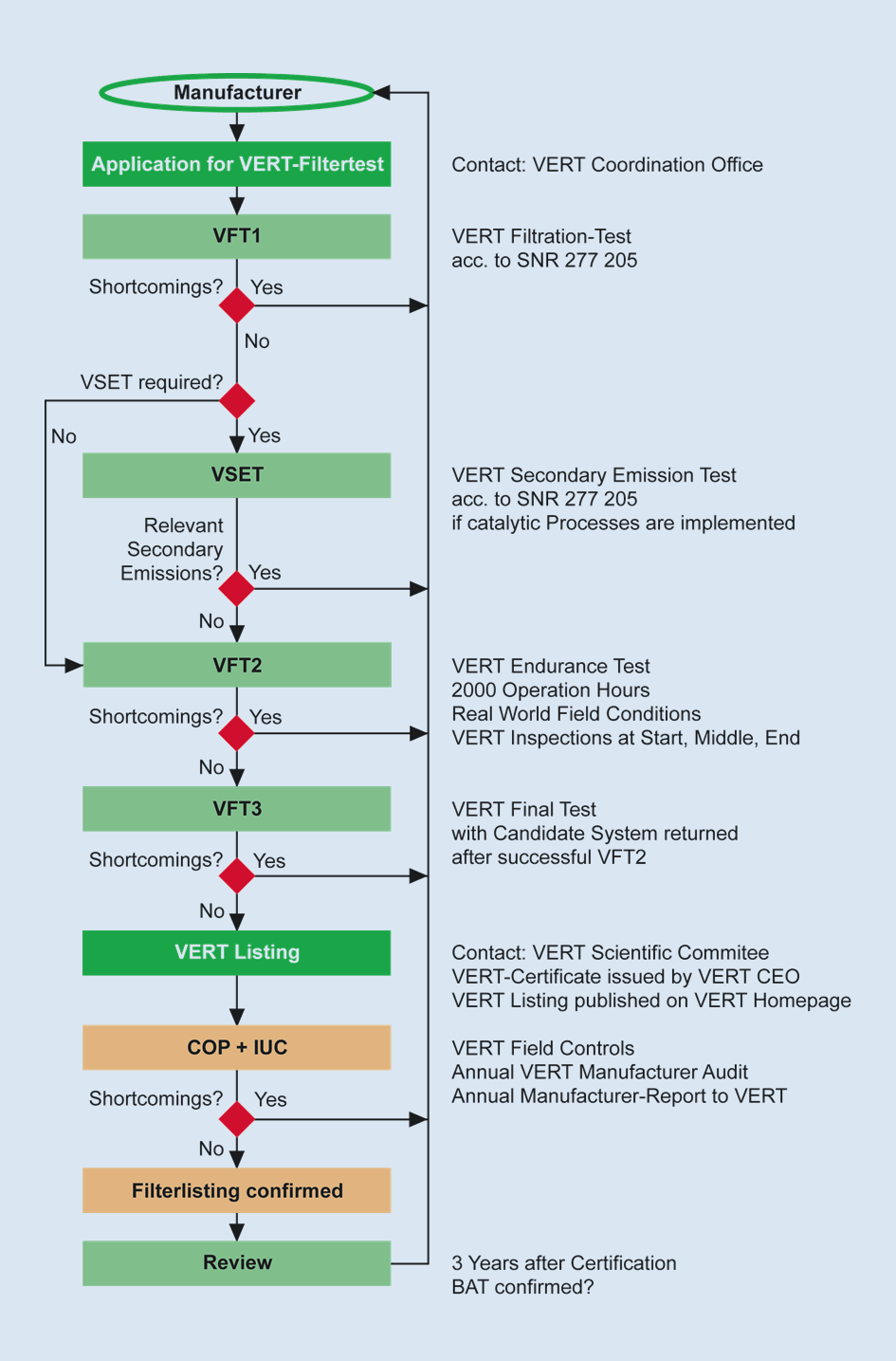

VERT® Certification of Diesel Particulate Filters

Worldwide efforts to curtail particle emissions from combustion engines have produced a plethora of technologies. Not all of them are Best Available Technology as required by law to eliminate carcinogenic substances. VERT® has been the pioneer in this field since 1993. The AKPF (Working Group for Particle Filters) subsequently collaborated with the regulatory authorities and industrial partners to formulate a set of criteria. These include highest requirements in filtering the alveoli-intruding solid particles, preventing secondary emissions, guaranteeing dependability and cost effectiveness of the systems and assuring the best retrofit practice. VERT® only approves systems which comply with the BAT definition and are proven in field deployment; which holds for both new and retrofitted older deployed Diesel engines.

High filter quality also results in cost effectiveness because it diminishes treatment costs for many serious ailments. These include cancer, cardiovascular diseases, allergies, asthma and probably even Parkinson’s, Alzheimer’s and other widespread diseases. VERT® is highly committed to implement the latest medical and scientific findings. The filter approval criteria will be periodically adapted to reflect technological advances. Hence, this filter list will be updated twice a year.

The VERT® Association aims to provide methods of very efficiently combating both emission toxicity and black carbon induced global warming. Particle filters facilitate a sustainable environment.

VERT® Approval Criteria of particle filter systems (extract)

- Filtration rate for solid particle number Particle Count Filtration Efficiency (PCFE) as defined by SN 277206, must be attained in average of all operating points, throughout the particle size range 20-300 nm.

| A | B | C | |

From year |

2000 | 2007 | 2016 |

New state |

≥ 95 % | ≥ 97 % | ≥ 98 % |

2000 hrs |

≥ 90 % | ≥ 97 % | ≥ 98 % |

- Particle Count Filtration Efficiency (PCFE) during regeneration. The criterion is the ratio of averaged values during the whole regeneration process

- Regeneration as specified by SN 277206

- Regeneration time < 3 % operation time

| 1 | 2 | 3 | |

From year |

2001 | 2012 | 2016 |

New state |

≥ 60 % | ≥ 70 % | ≥ 80 % |

2000 hrs |

≥ 60 % | ≥ 70 % | ≥ 80 % |

- Overall PN-peak reduction during free acceleration ≥ 95%

- The criterion is the ratio of the peak values

- Measurement as specified by SN 277206

VERT® Tests Basis – Swiss Standard SN 277206

Secondary Emissions

Secondary emissions are all compounds which were not present in significant concentrations in the exhaust gas of the base engine before retrofit. Formation of relevant amounts of such toxic reaction products is not permitted following.

Compared to baseline engine values, no relevant increase of the following toxic emission components is permissible in the treated exhaust gas after the PFS:

- Gaseous secondary emissions: principally NO2, Dioxins and Furans, PAH and Nitro-PAH

- Aerosols of sulfuric acids

- Metal oxides (e.g. ash particles from additives, engine wear, lube oil additive packages )

- Mineral fibre emissions in the WHO defined size range L<3 μm; D<5 μm

- Limit Values for NO2

Average NO2 increase over engines baseline due to catalytic conversion of engine-out NO must not exceed 20 % in relation to NO upstream filter for all systems certified from 2016. This value shall be determined as per SN 277206.

| A | B |

| Until year 2015 | From year 2016 |

| No limit |

ΔNO2/NO<20% |

- Filter systems converting engine-out NO into NO2 can only be used in environments where the concentration of NO2 in ambient air is well below the locally valid air quality limits.

Relevance of other secondary emissions

Increase of trace substances like Dioxins, Furans, PAH, Nitro-PAH and metal oxide particles <400 nm are deemed “relevant” when the exhaust gas after the PFS exhibits concentrations, exceeding thrice the engine emission without PFS, at the same operating points.

Pressure Loss

- Fresh filter: < 50 mbar at high idle

- Regeneration threshold: < 150 mbar

- Maximum soot + ash burden: < 200 mbar (95% percentile)

- Alarm episodes > 5 sec above 200 mbar

- Special cases: If tolerated by the operator and the engine manufacturer, a pressure loss of maximum 300 mbar can be accepted at maximum soot+ash burden. Engines with uncontrolled EGR shall not be operated against more than 120 mbar back-pressure, the permissible level might be even lower and must be agreed upon by the engine manufacturer and the operator.

Function Monitoring OBD

- Continuous electronic monitoring of backpressure and exhaust temperature

- Measurement every second, storage on 1 minute base

- Alarm signal and alarm logging when maximum back-pressure is exceeded

- Additive (if used): dosage shut off automatically when filter damage is detected.

- Special situations: For PFS which are externally regenerated or replaced for regeneration as well as for temporary filters (so-called snap-on filters), the electronic monitoring can be substituted. Permitted is instead a simple pressure gauge with visual or acoustic alarm.

- In case the operator does not properly react to the alarms, the OBD-system shall activate an automatic safety feature, which might be torque reduction, re-start limitation of even engine shut-off.

Durability, Maintenance and Warranty

- Life expectancy > 5000 operation hours

- Usable hours until cleaning > 2000 operation hours

- Maintenance interval > 500 operation hours

- Guarantee on materials and function > 2 years or 1000 op. hours (whichever is earlier)

Criteria for VERTdePN-Systems

- NOx - Reduction

| A | B | C | |

| New state | ≥85% | ≥75% | ≥65% |

| 1000hrs. | ≥75% | ≥65% | ≥55% |

- NH3-emission <25 ppm

- N2O-emission <10 ppm