Filters

Functions & Types

Filtration |

Regeneration |

Monitoring |

Noise Reduction |

|

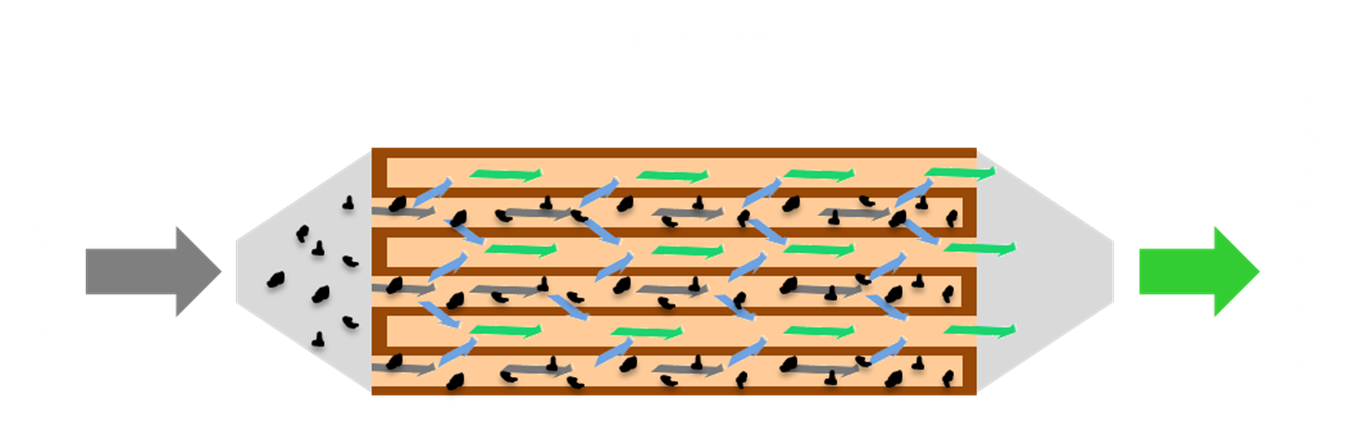

…retaining soot and non-combustible particles by using adequate filtration substrates |

… burning (regenerating) of the soot collected in the filter |

… of the filter system operation with minimum temperature and pressure (Data-logger). Storing the data in an ECU (Electronic Control Unit) |

Particle filters replace mufflers and therefore have to achieve at least an equivalent level of noise reduction |

Filtration

VERT® only approves and certifies “closed systems” because only these types fulfill the required particle reduction rate of > 97 % efficiency based on particle numbers.

Particle Filter - Closed System

Regeneration

All solid particles of the exhaust gas are accumulated inside of the particle filter:

Regeneration relates to the removal of soot from the filter. The particle filter system has to perform this process by itself.

Cleaning refers to the removal of non-combustible components such as engine oil ashes, metal particles and silicates from the filter. This is part of regular maintenance.

- Soot will be continue or discontinue regenerated out of the filter. Soot ignites at approximately 600 °C. Since such a temperature is never reached at the location of the particle filter in the off-gas stream, technical measures are necessary in order to constantly or periodically remove soot from the filter element.

- Non-combustible remains, e.g. ashes from engine oil will lead to service of the filter device.

Filter Regeneration and Filter Cleaning are NOT identical!

Particle filter systems have got to be regenerated (i.e. the soot has to be removed from the filter) so that the exhaust backpressure will not rise to too extreme levels.

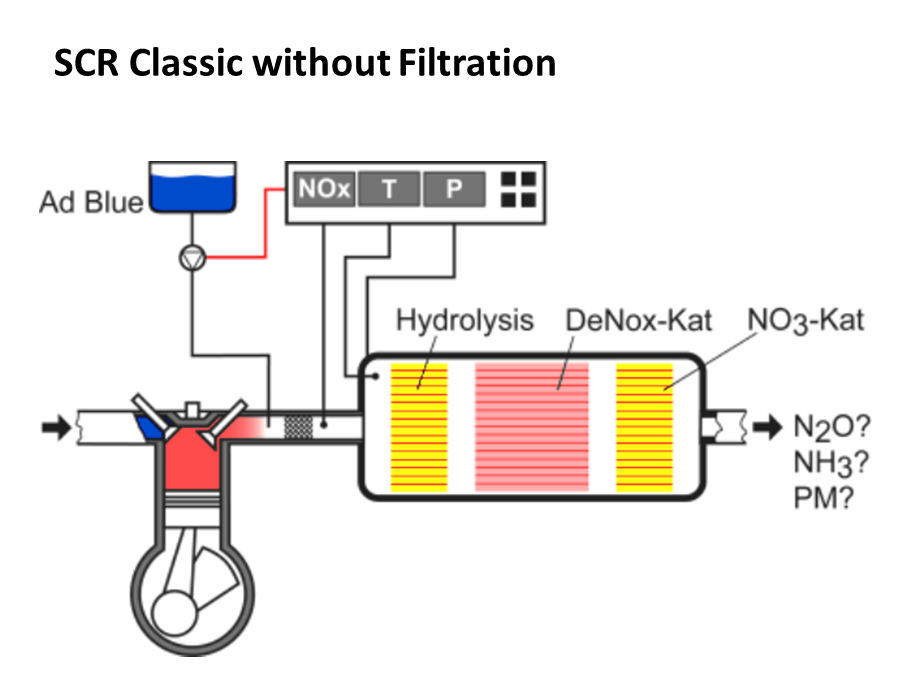

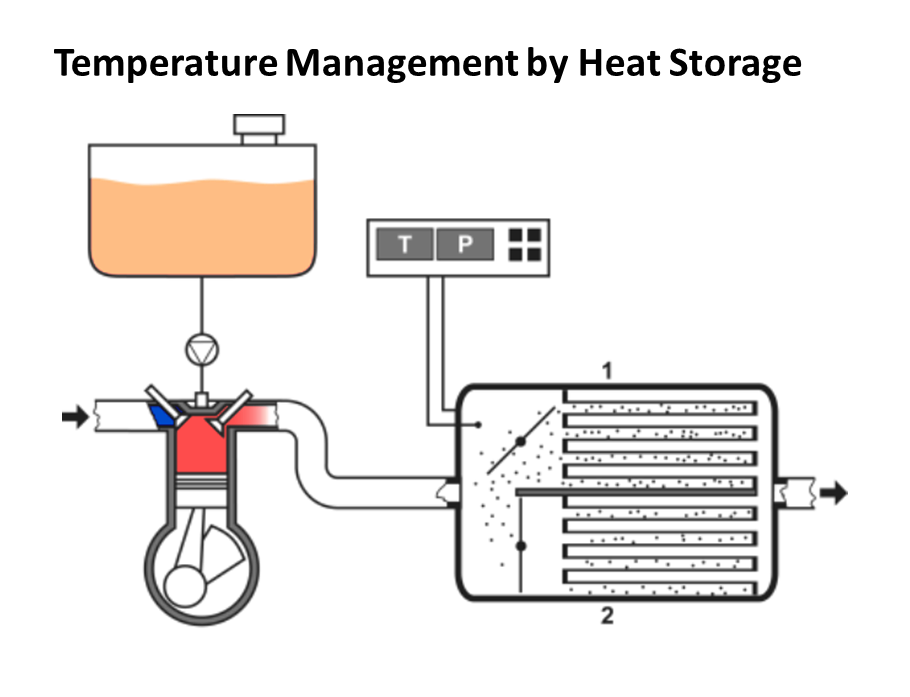

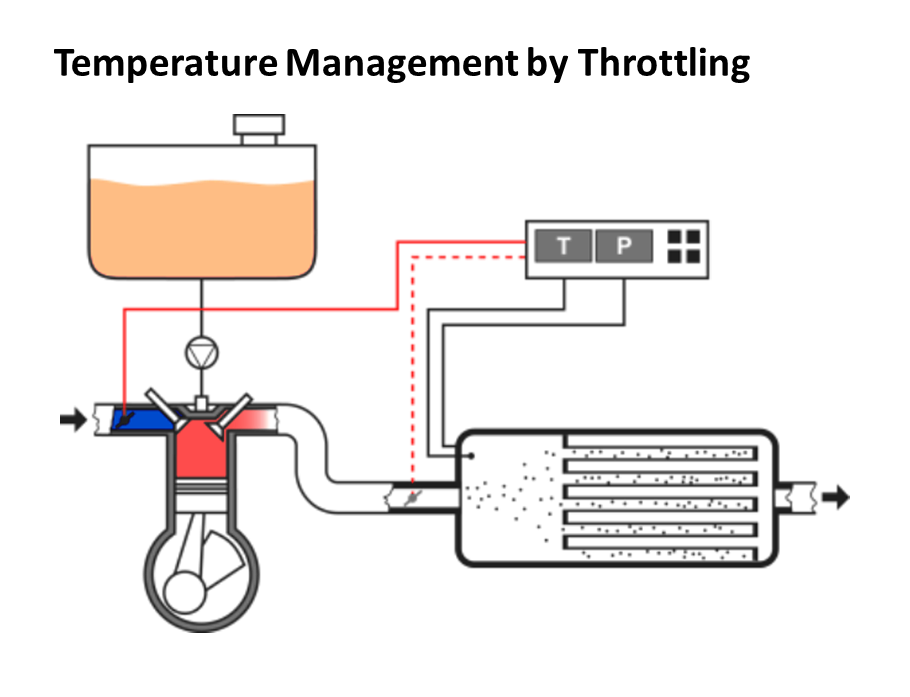

There are different types of regeneration systems:

- “Passive regeneration systems”

- “Active regeneration systems”

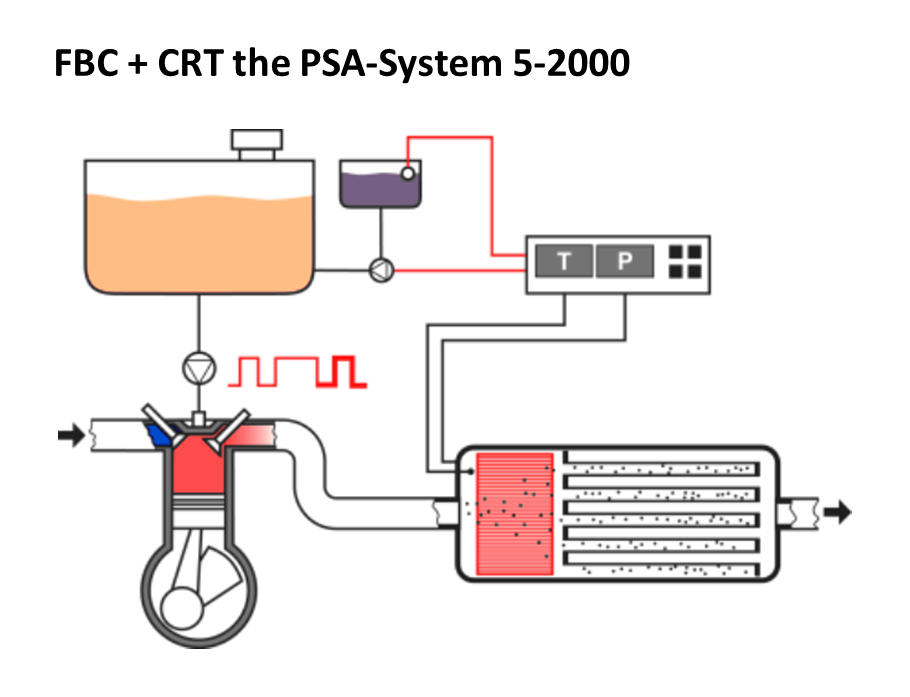

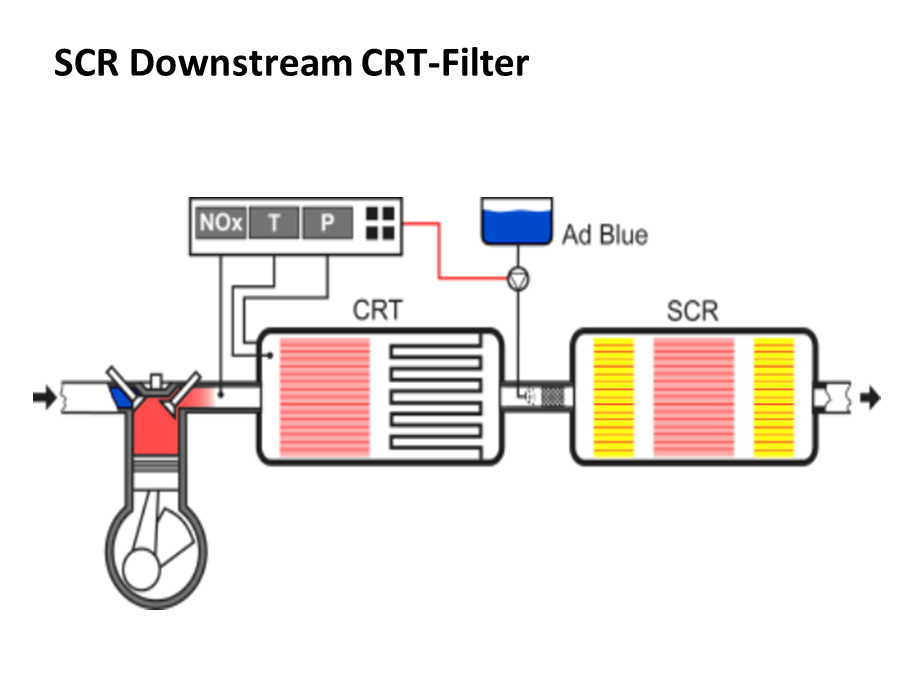

- Combinations between passive and active systems

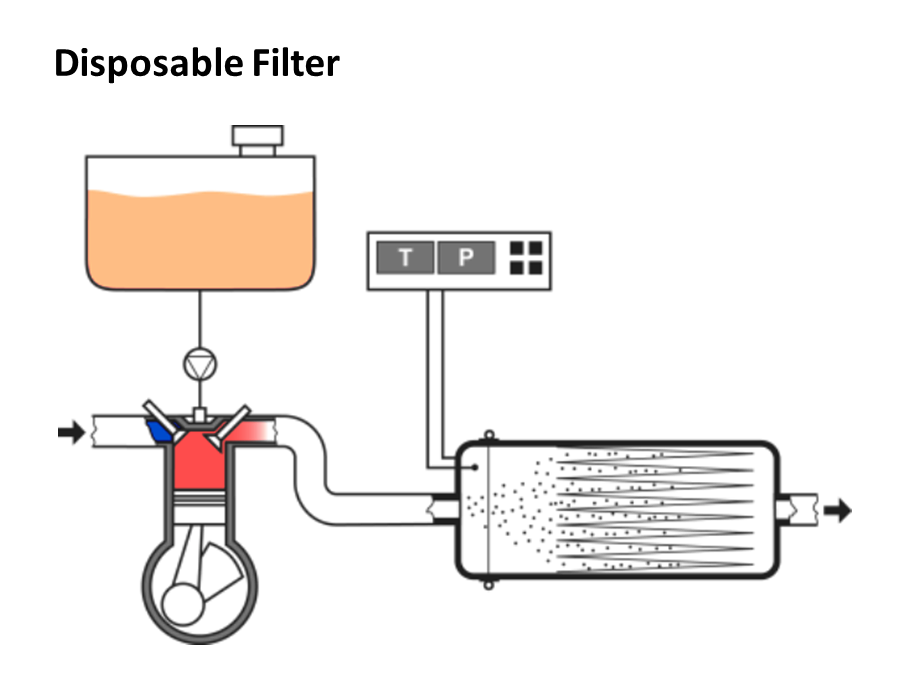

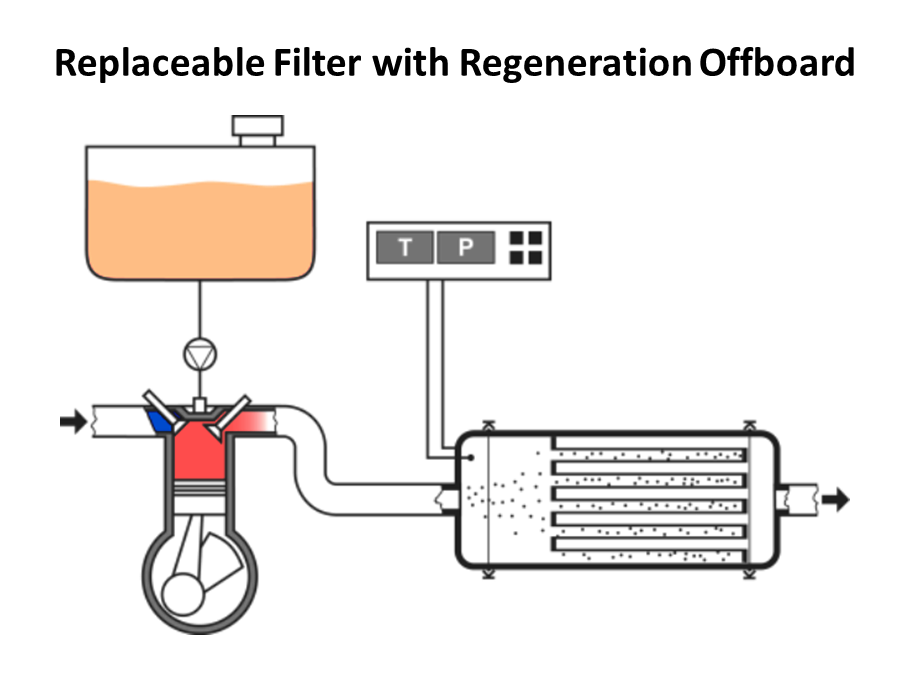

- “Exchangeable or Plug-on filter systems”

“Passive regeneration”

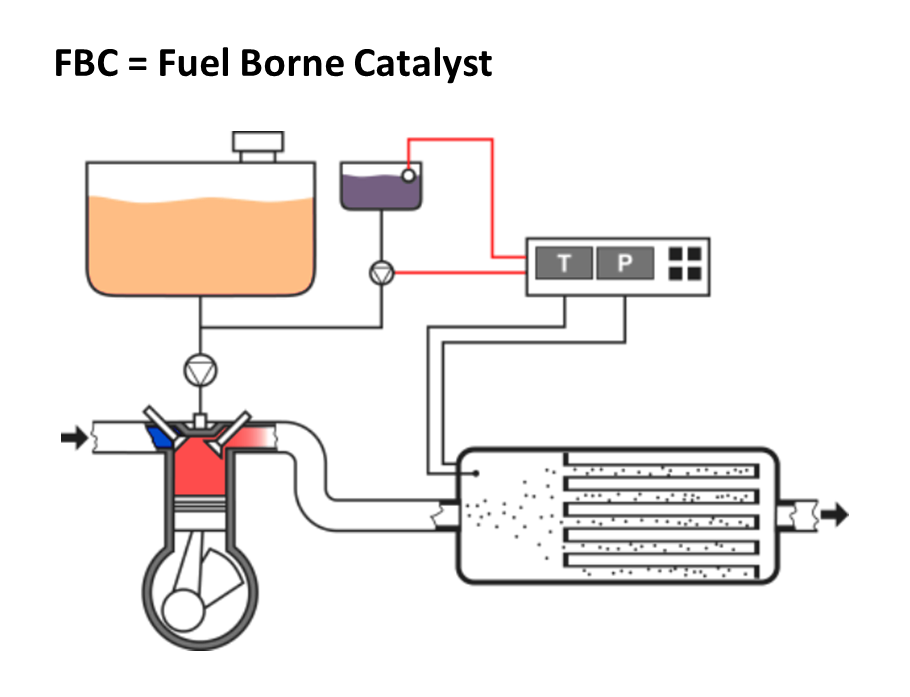

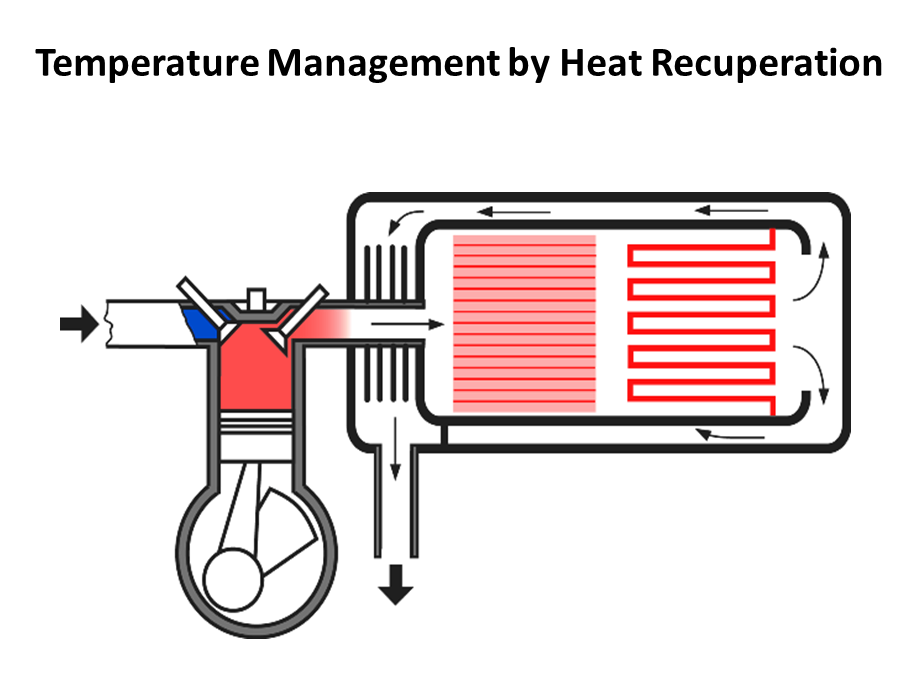

Passive filter systems convert soot separated on the filter without an external supply of energy, as long as exhaust gas temperatures are sufficient.

They depend on the exhaust gas temperature, the duration of the temperatures generated and state of the exhaust gas flow.

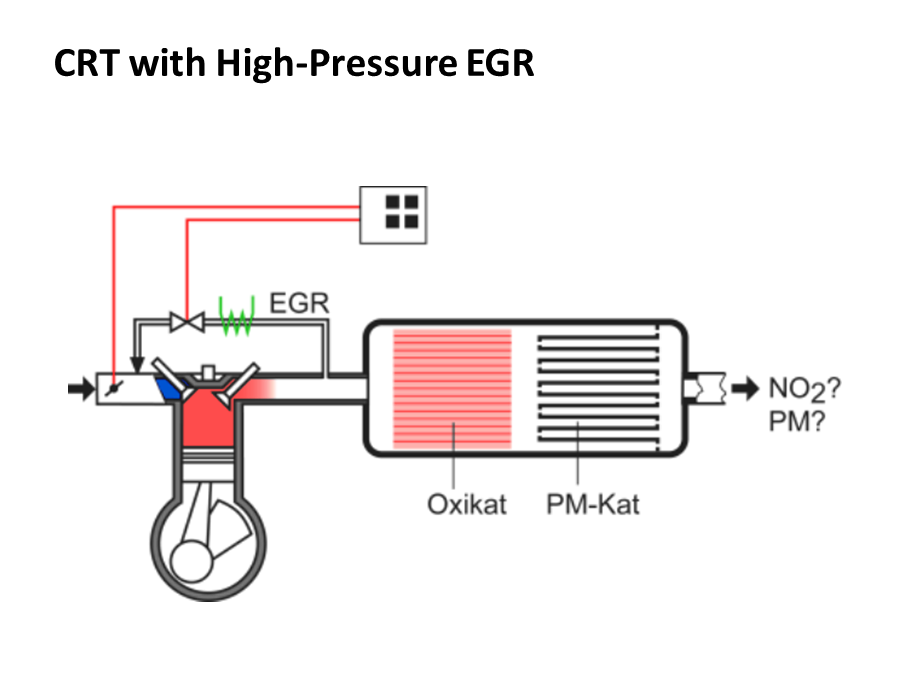

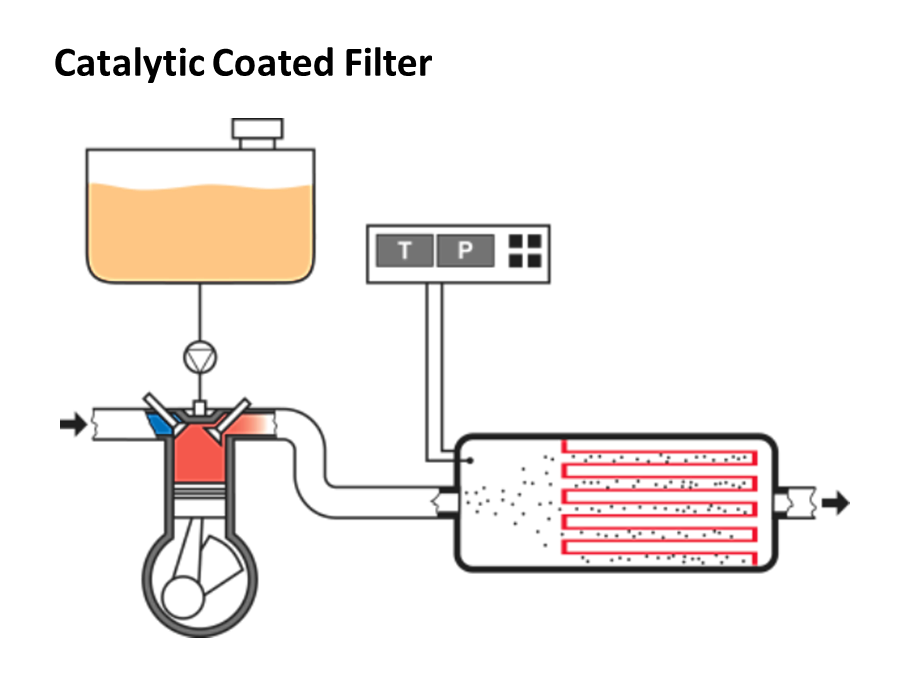

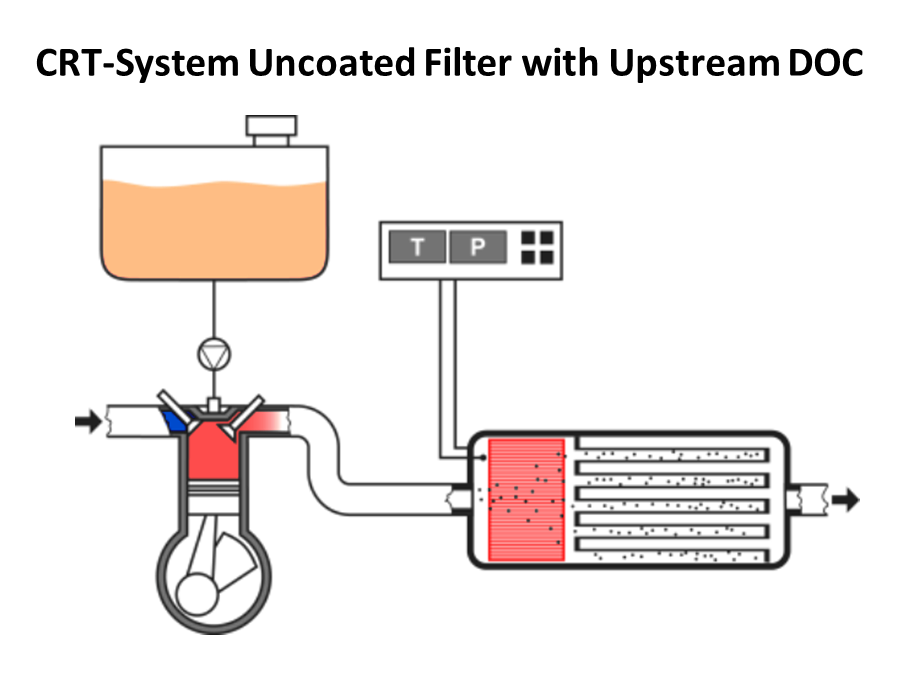

The regeneration is induced by the gas NO2, through oxidative coating or via the addition of additives to the fuel.

Prior to the retrofit, the characteristics of exhaust gas temperature have to be tested thoroughly during realistic duty cyles.

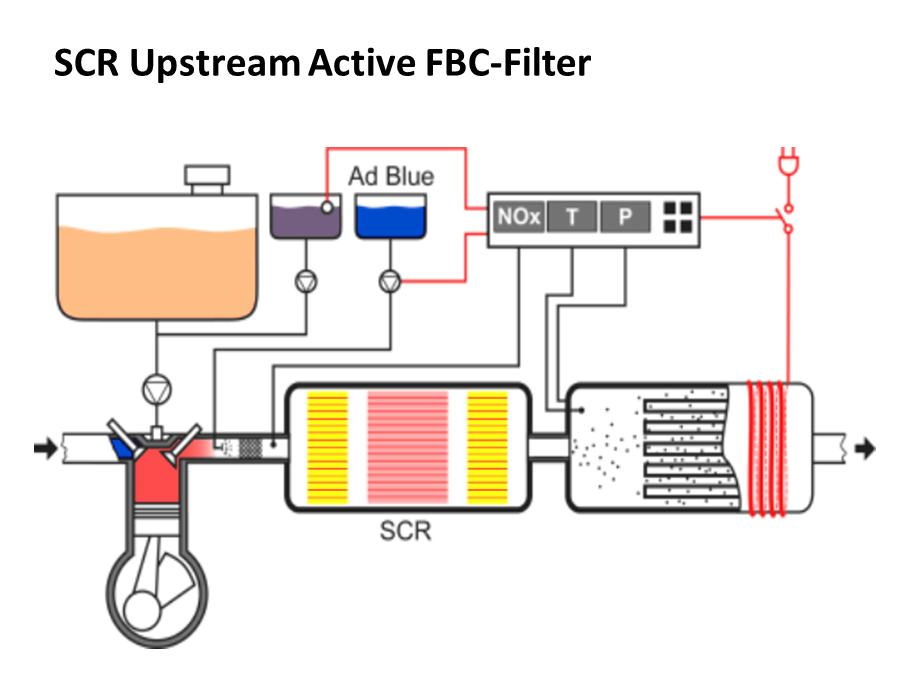

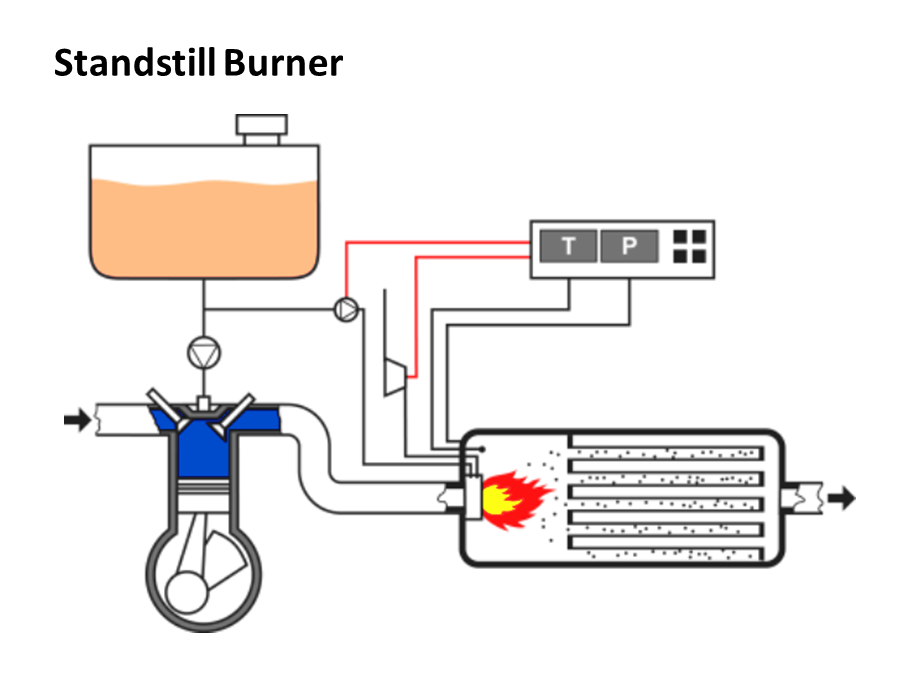

“Active regeneration”

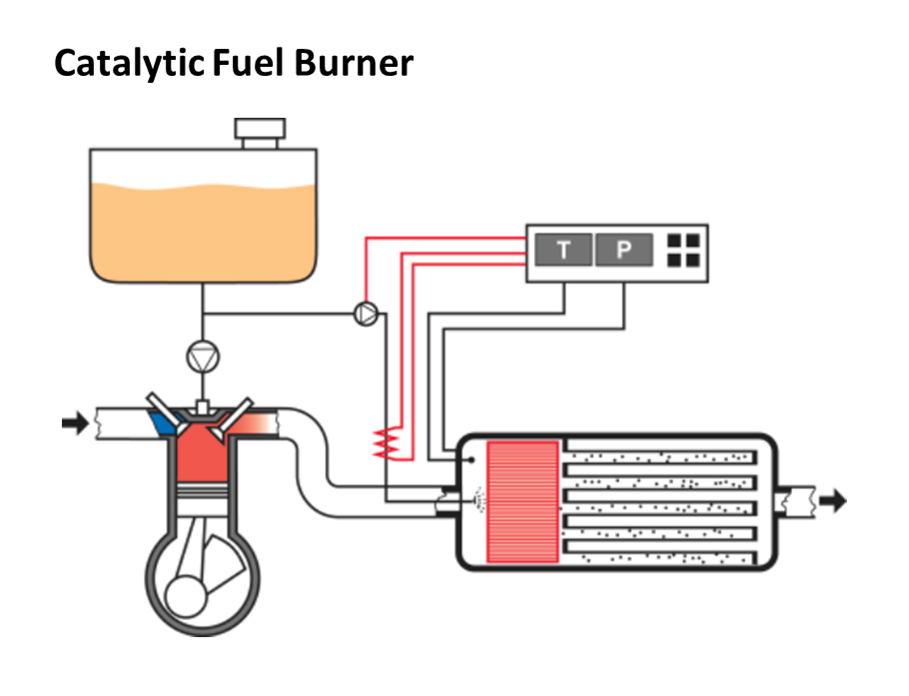

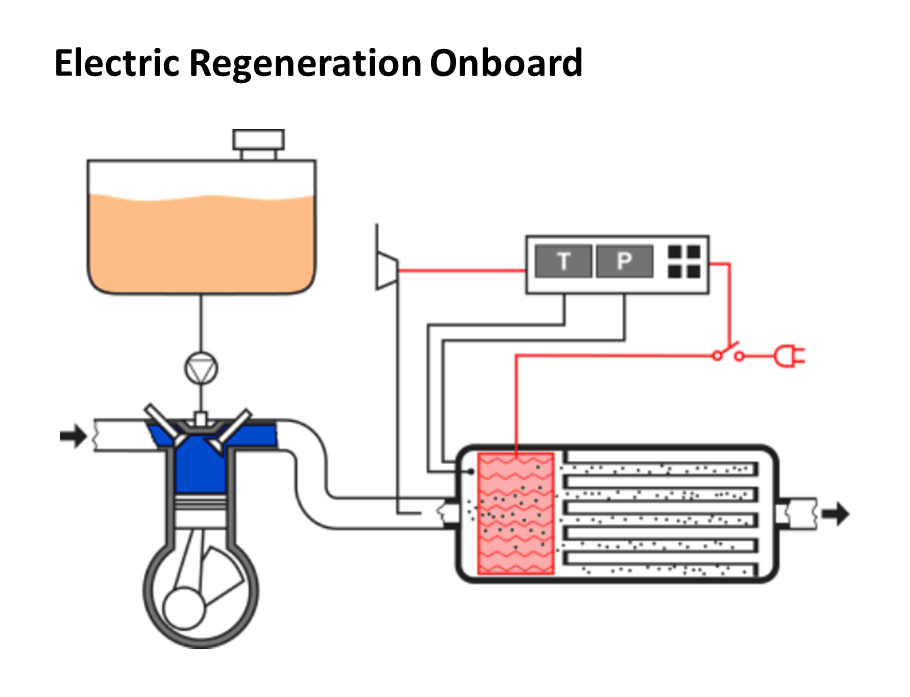

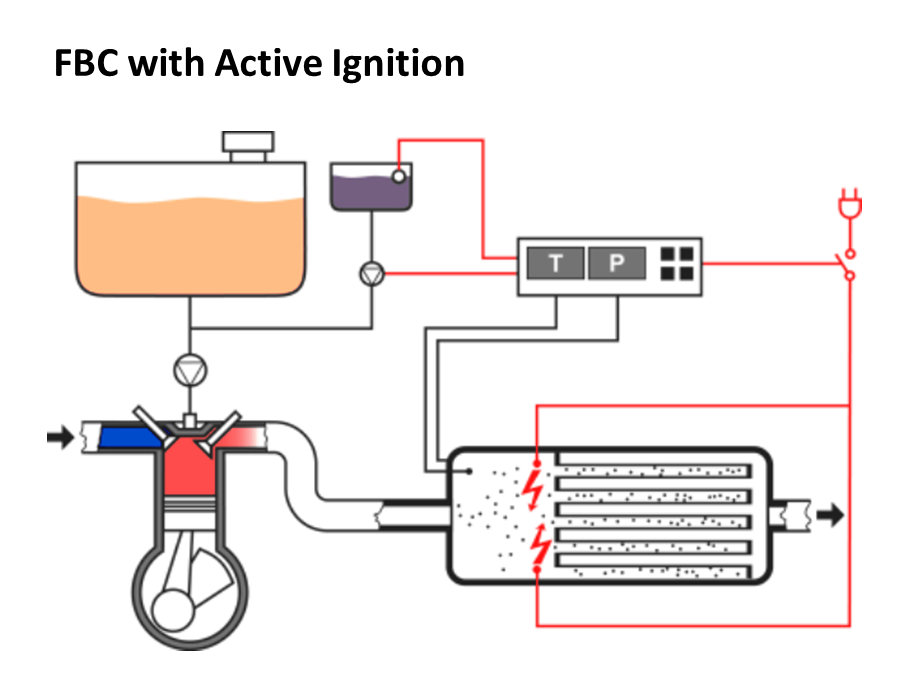

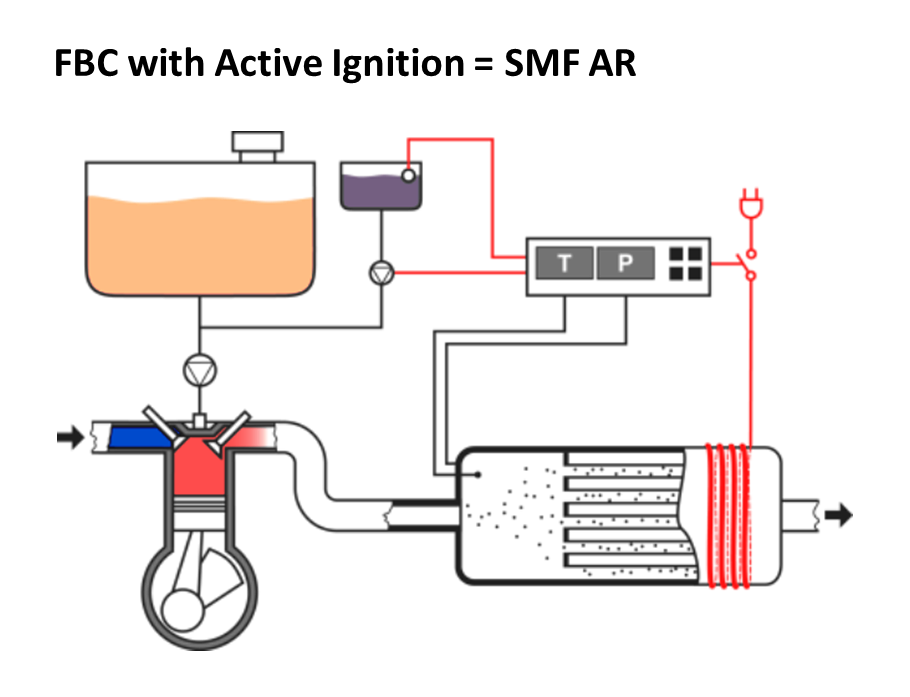

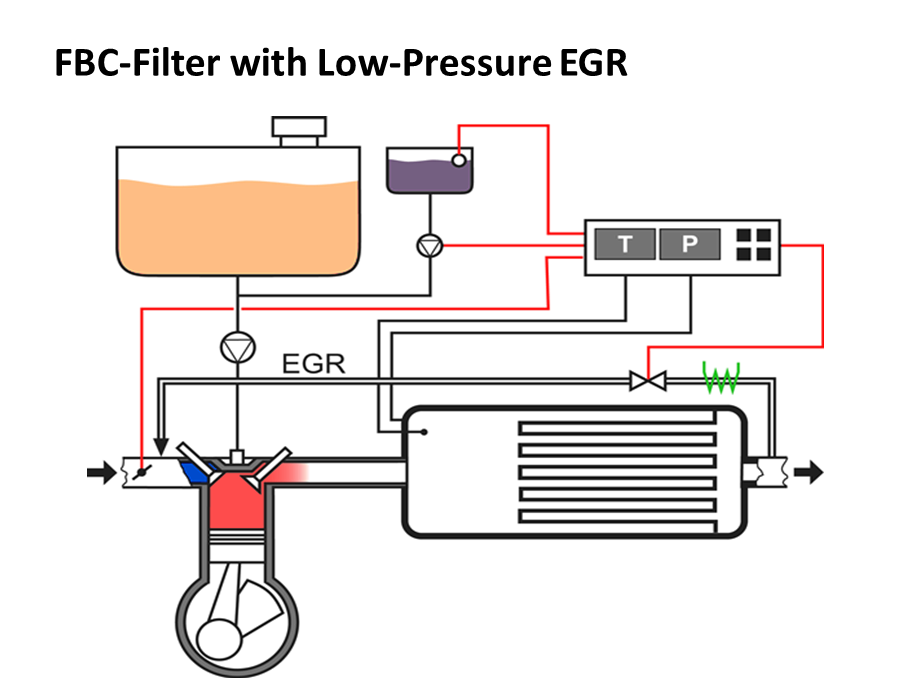

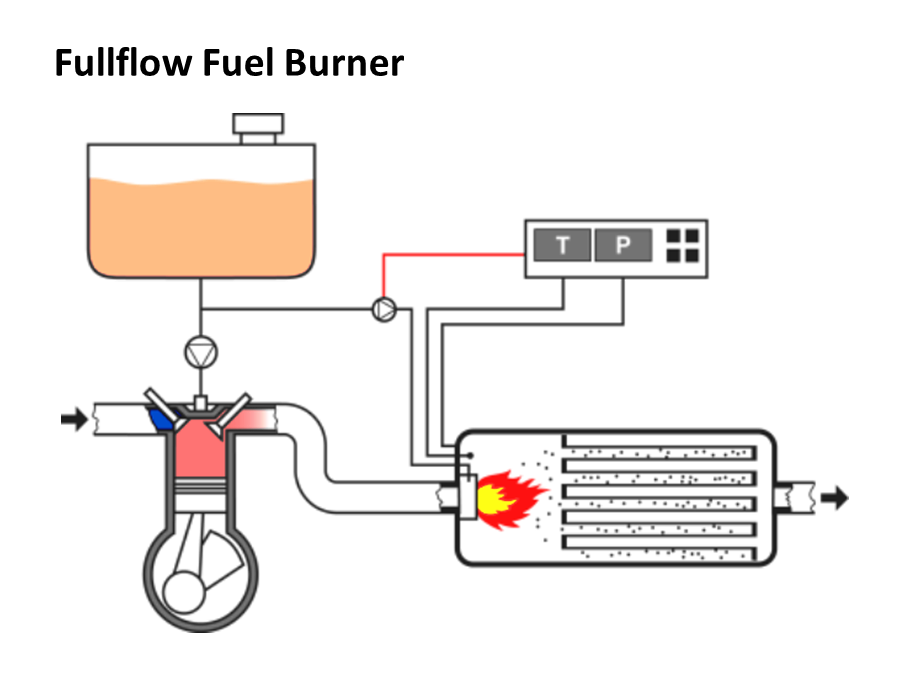

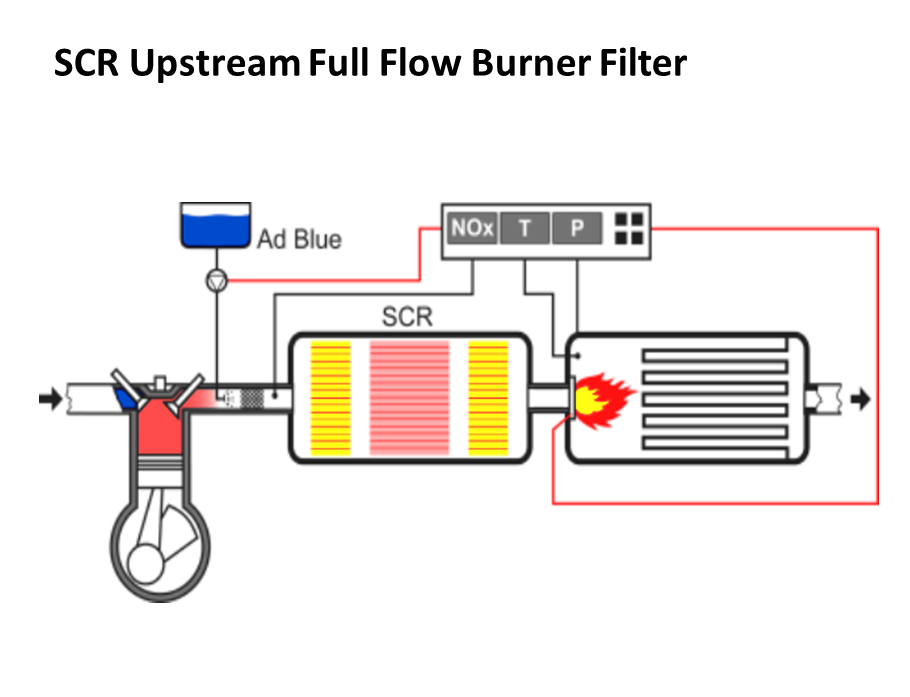

In order to ignite the soot, the filter has to be actively supplied with energy.

Various process technologies are used to do so:

- Fuel injection system in combination with a catalyst (catalytic burner).

- Full-flow burner system: the necessary temperature is generated by a burner system, while the machine is operating at full capacity.

- Standstill Burner: the necessary temperature is generated by a burner system but for the regeneration the machine has to be switched off.

- Electrical power supply: is also possible in combination with additives in order to reduce the ignition temperature to a level where electrical onboard power can ignite the soot in the filter to regenerate.

“Exchangeable and Plug-on filter systems”

Exchangeable filter systems are systems that cannot perform the regeneration process by themselves and therefore have to be cleaned externally or exchanged in certain intervals

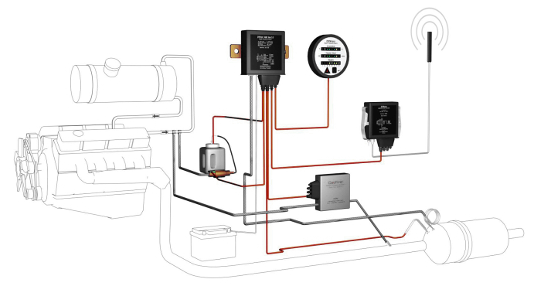

Monitoring

Particle filter systems shall be equipped with an electronic control device.

If the counter-pressure exceeds the limit value, a clearly perceptible visual alarm (a warning light in the driver cabin) is activated.

Optionally, the main alarm can be preceded by a pre-alarm to leave efficient time for filter maintenance.

In small intervals (1...30 sec.), the electronics record minimum the exhaust gas temperature and back pressure.

Additional features like lambda control or gsm modules can support better service and sustainability.

Monitoring System

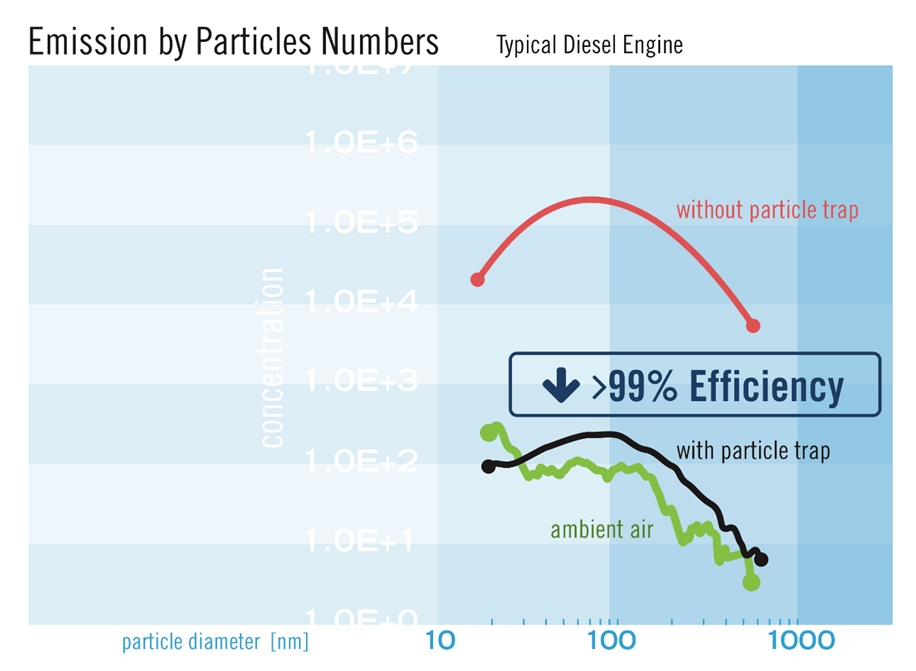

Effiniency

Size distribution of an typical diesel engine with and without closed DPF

Certified Particle Filter Systems for Internal Combustion Engines